Introduction

The electric car seemed like a far-off choice for most people in the modern world, unlike the fast adoption of fuel-based cars. Researchers actively sought the electric car at the beginning of the 20th century, but the readily mass-produced gasoline-powered car snuffed off enthusiasm for the idea. The desire for a more ecologically friendly mode of transportation was dormant between 1920 and 1960, but it was revived by concerns about contamination and the depletion of natural resources. There has been a significant increase in the cost of production. The good news is that modern car electronics are so advanced and compact that they are perfect for use in electric vehicle applications.

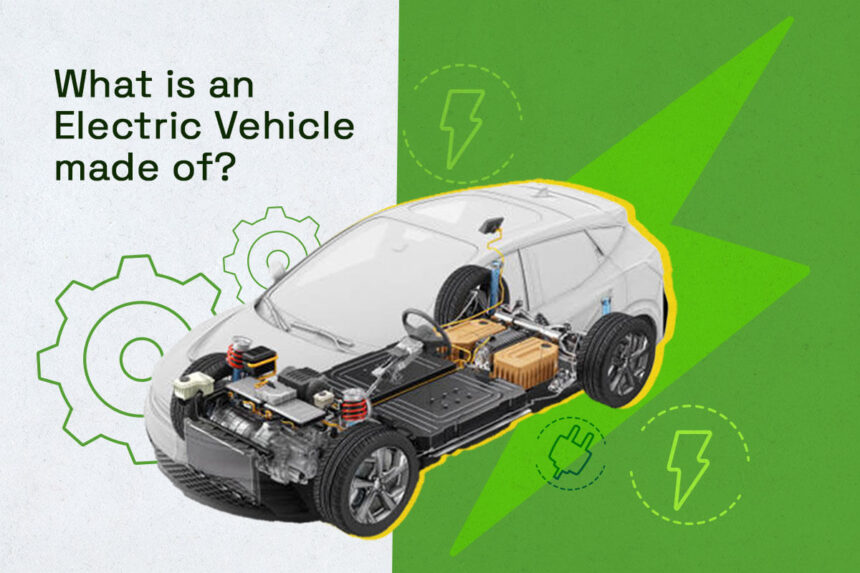

What are the components of an EV?

The secondary-type batteries used in electric cars are rechargeable storage cells, as opposed to battery systems, which have a finite amount of time for chemical processes to create energy. To improve the distribution of weight and protection, batteries are arranged in a T-shape down the centre of the vehicle, with the top of the “T” located at the back. Lead-acid, nickel-iron, nickel-zinc, and zinc-chloride batteries have all been used to create electric vehicle batteries.

The weight of the electric vehicle has also consistently presented design challenges. While the motor, coolant system, and other particular powering equipment make up only 25% of the weight of an internal combustion-powered automobile, the battery and electric propulsion system often account for 40% of a load of an electric vehicle.

The hydrogen used in fuel cells serves as a chemical source for the electrons needed to produce power. These chemical sources include ethanol, methanol, and gasoline; when gasoline is utilised, fuel cells utilise it more effectively than internal combustion engines do. Fuel cell models have undergone successful testing, and in 1998, the Japanese started producing hybrid vehicles. The lithium-ion battery, which has a power density three times larger than that of a lead-acid battery, is another potential hope for electric cars. New-age manufacturing has propelled the technology ahead.

What components make an Electrical Vehicle?

The space frame, or “skeleton,” of an electric vehicle is constructed of aluminium to be both sturdy and light. To further reduce weight, aluminium is used for the wheels in place of steel. Magnesium is a lightweight metal that is used to make seat frames and the centre of the steering wheel. The frame is constructed from reusable impact-resistant composite plastics.

Batteries for electric vehicles are made out of plastic dwellings containing metal anodes, cathodes, and electrolytes.

Metal and plastic components of the motor or traction system do not require lubrication. It also has sophisticated electronics that govern the conversion of energy from the batteries into driving power and the flow of that energy.

The onboard computer system, which controls locks, glass, a tire-pressure monitoring system, air conditioning, starting the car, the CD player, and other features common to all automobiles, is a crucial component of the control panel located in the console.

The dashboard cover, door liners, and seats are made of plastic, foam cushioning, vinyl, and textiles. Rubber tyres are used, however, they differ from regular tyres in that they may be inflated to greater pressures to reduce rolling resistance and save energy. In order to save electricity, the sealant in the tyres of electric cars also immediately plugs any leaks

.

Important technical aspects to remember

In the construction of electric cars, the batteries that store energy and power the electric motor are a science unto themselves. Various solutions are being researched to discover the most efficient batteries that are both safe and economical. a motor that uses electricity to transfer to the drive train after being converted from battery power. These locomotion or propulsion systems for electric automobiles employ both direct-current (DC) and alternating-current (AC) motors, however, AC motors don’t need brushes and need less upkeep.

Speed may be altered thanks to a controller that manages the battery’s energy transfer to the motor. Because they absorb too much of the energy directly, resistors utilised in other electric devices for this purpose are impractical for automobiles. SCRs (silicon-controlled rectifiers) are employed as an alternative. They enable the battery to supply the motor with its full power, but in bursts, preventing the battery from being overloaded and the motor from being underpowered.

Electric vehicles may employ any type of braking system, however, regenerative braking systems are particularly recommended since they recover some of the energy lost during stopping and direct it back to the battery system.

There must be two different charger types. The electric car must have a full-size charger installed in a storage shed to charge up overnight, but a mobile charger is included as standard equipment in the trunk so the batteries can be refuelled in an emergency or while the driver is away from home or a charging station. An induction charger for electric vehicles was developed with a paddle that is put on the front end of the vehicle because of concern for safety. To replenish the batteries and reduce the risk of electrocution, it employs magnetic energy.

Conclusion

The complex yet simple nature of our new age of Electric Vehicles makes them truly commendable technological marvels. It is important to know the components of the car or automobile so we can use it to its best abilities.